Engineering Capabilities

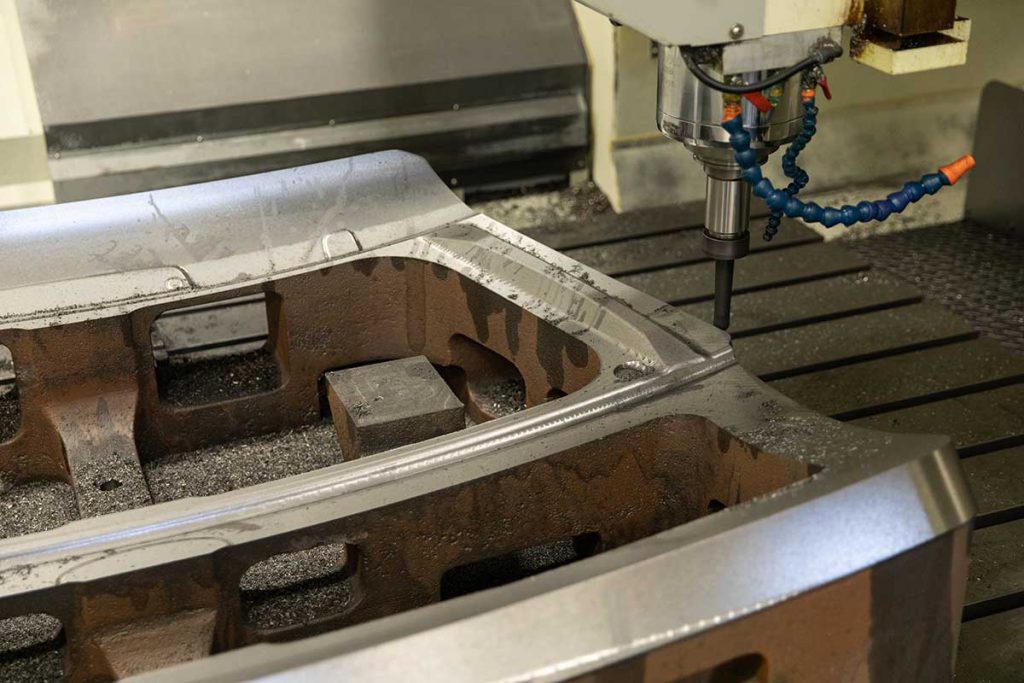

Tooling and Fixture Designs:

- Complete in-house prototype and low volume production tool and fixture designs.

- Stamping tools, weld assembly fixtures, laser trimming fixtures, CMM or non-contact scanning fixtures.

Software Platforms: Catia, NX, Tebis, WorkNC, GOM

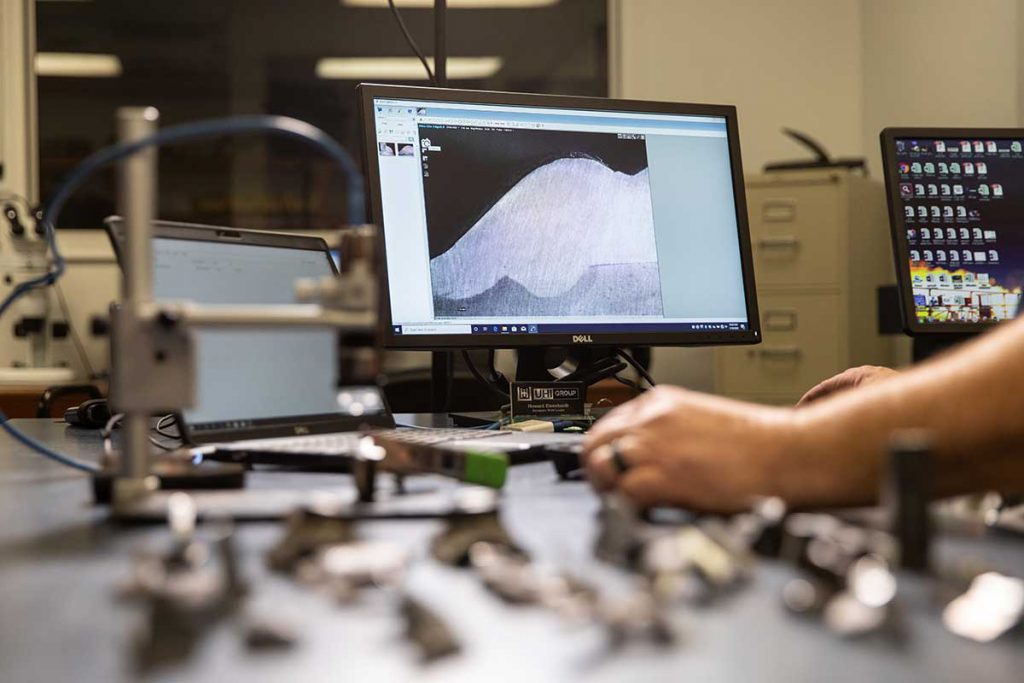

Forming Simulations:

- Full process and full-cycle validation – FLD Criteria: including splitting and excessive thinning, compression and wrinkling potential, failure analysis, spring back prediction and surface deformation. Spring back compensation based on virtual simulation results.

Software Platform: Autoform Incremental R8

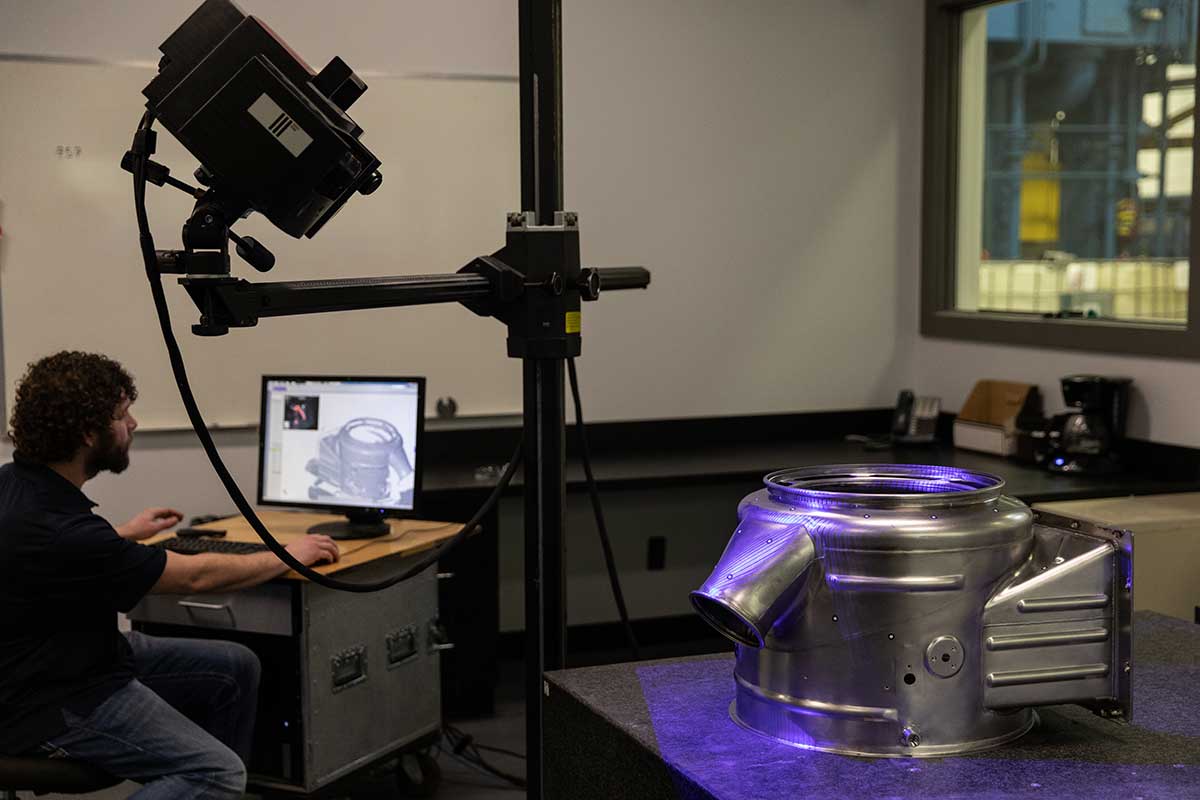

Reverse Engineering Services:

- Spring back compensation is based on non-contact scanning of physical parts and tooling.

- Damaged tooling repairs, engineering changes, hybrid tooling models utilizing scan data and native product models.

- On-sight scanning services in our temperature controlled studio, or off sight scanning at your facility. First article inspection per AS9201, in-process inspection with advanced reporting and analysis utilizing discus Software and Net-Inspect database. Software/Hardware: Atos III triple scan 8m pixel blue light scanning system, TriTop photogrammetry, GOM Professional, Catia, Tebis.

Software / Hardware: Atos lll triple scan 8m pixel blue light scanning system, TriTop photogrammetry, GOM Professional, Catia, Tebis

Our engineering team has a long track record of success in manufacturing for the aerospace, automotive, defense, and commercial vehicle sectors. Regardless of the project you have in mind, we will help you go from the drawing board to a high-quality finished product.