UHI Group: Enhancing Precision and Efficiency with In-House Fixtures and Design

Introduction

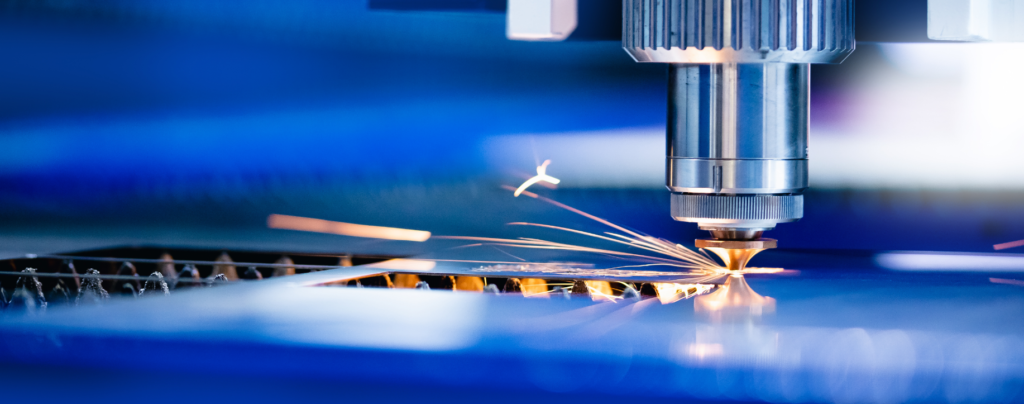

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. Companies that can seamlessly integrate design, production, and quality control gain a competitive edge. One such company that exemplifies this approach is UHI Group (Ultimate Hydroforming, Inc.). With decades of experience, UHI Group has consistently pushed the boundaries of innovation, and a key aspect of their success lies in their in-house fixture design capabilities.

The Role of Fixtures

Fixtures play a crucial role in manufacturing. They ensure consistent part positioning, reduce setup time, and enhance repeatability. Traditionally, companies outsourced fixture design, leading to delays, communication gaps, and compromises in precision. UHI Group recognized this challenge and decided to take matters into their own hands.

UHI Group’s In-House Fixture Design

1. Expertise and Customization:

2. Reduced Lead Times:

3. Cost Savings:

4. Quality Control Integration:

Designing for Success

UHI Group’s commitment to in-house excellence extends beyond fixtures. They also embrace in-house design capabilities:

1. CAD and Simulation:

2. Collaboration Across Disciplines:

3. Prototyping and Iteration:

Conclusion

UHI Group’s commitment to in-house fixture design and overall design excellence exemplifies their dedication to precision, efficiency, and customer satisfaction. By seamlessly integrating fixtures and design, they continue to shape the future of manufacturing. As industries evolve, UHI Group stands ready—with CAD software humming, fixtures aligned, and innovation at the forefront—to deliver exceptional results.

In the world of manufacturing, UHI Group isn’t just a company; it’s a beacon of in-house ingenuity.